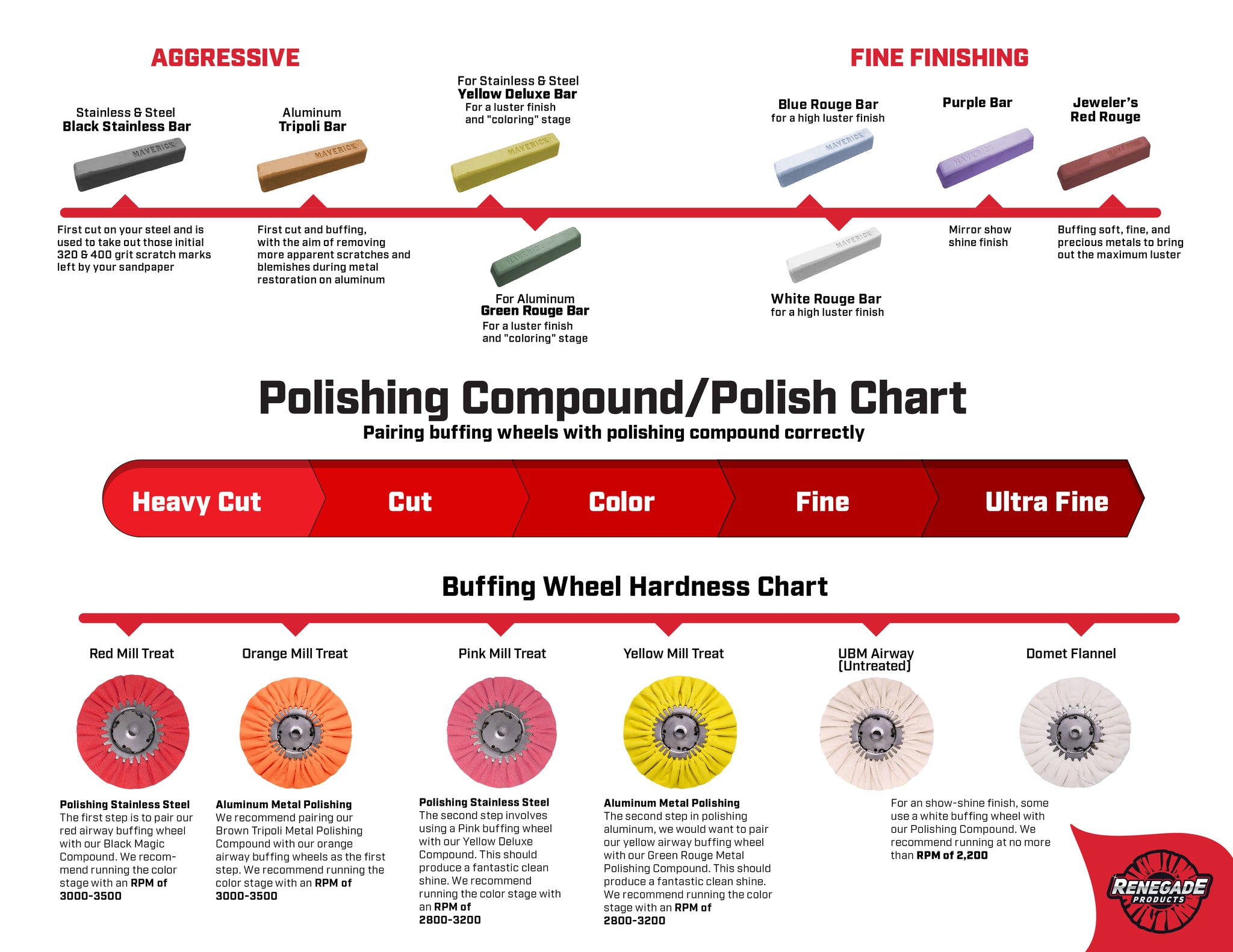

BUFFING WHEEL COLOR CHART

Below you will find our buffing wheel and buffing compound chart that displays from stiffness to hardness (buffing wheels) and from coarseness to finest finishing (compound bars).

Below is a table showing the maximum safe operating speed for each size of buffing wheel:

WHAT ARE POLISHING COMPOUNDS MADE OUT OF ?

Rouge bars or Polishing compounds are made using a large mixer that will heat and churn ingredients such as abrasive grains, stearic acid, tallow and wax. The exact mixture of each and type of abrasive grain used will depend on the color and its application. For instance, black and brown compounds are for coarse cutting and removing 400 and 600 grit scratch marks on stainless steel and aluminum. One of the most popular bars in the industry which is a green rouge, contains green chromium oxide which gives it is color and darker, rich luster on aluminum or stainless steel. Bars such as the competition purple are as fine finishing as you can go without going to a jewelers red rouge (which is not necessary in truck polishing.) Red rouge utilizes a red chromium oxide (micro rust particles) to do fine finishing on precious metals like gold or silver.

What tools do you need to have to high speed metal polish?

What other items do you need for metal polishing?

Makita 9237C, Makita GA7021, or DeWalt DWP849X when it comes to polishing machines.

Full Face Respirator - Don't skimp on these, you don't want metal dust and polishing products in your lungs! This is the best respirator for metal polishing.

Masking tape is an absolute necessity when high speed polishing.

Makita Random Orbital Sander - Most popular sander for metal polishers