Renegade's original Red Line

•Soap & Dressing & Savage APC

Kits

$49.00

•2oz Bottles of hand sanitizer and surface disinfectant spray to leave in your vehicle, purse, or other convenient areas

•Full size bottles for work or home

$49.00

$49.00

$49.00

Menu title

This section doesn’t currently include any content. Add content to this section using the sidebar.

Your headline

Image caption appears here

$49.00

Add your deal, information or promotional text

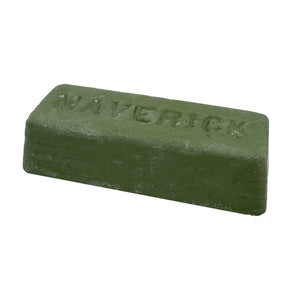

CBTT121-JBAR

$8.00 USD

Renegade Products is the premier manufacturer of polishing compounds that are robust in quality due to our use of premium raw materials. We do not use cheap fillers in our polishing compounds like other manufacturers that prioritize profit over bar quality.

Our cutting compounds are meant to be used with our stiffest buffing wheels to do most of the heavy lifting when it comes to removing the oxidation and surface imperfections on your polished metal projects.

Our metal polishing compounds are used with our Airway Buffing Wheels to increase the effectiveness of the wheel while being used during the cutting, buffing, and polishing process. Some are of a coarser consistency and are usually used to remove scratches while the others are finer, which lends to them being used to shine and finish your work. They should be applied to airway buffing wheels by coating the edges of the airway buffs like below:

Prepping is almost entirely all about sanding. We recommend starting with 180 grit for most wheels and stepping forward to 220 grit, and finishing with 400 grit sanding discs. Most polishing, for aluminum, can be polished well after prepping with 400 grit—finer grits are not usually necessary before polishing with tripoli compound.

Two points to keep in mind that as an alternative to sanding discs one of most popular products is the buff and blend prep discs. Most users will not need green buff and blend discs as those are often used more for concrete wheels. The blue buff and blend disc can help remove dirt, grime, and rust from a wheel to provide a clean surface to begin polishing with compound. We do recommend hitting an aluminum wheel with our maroon satin airway prior to going to polish with tripoli compound as the blue buff and blend disc may leave some hash marks that won't come out without a finer sanding of 400 grit or the maroon airway.

To determine which polishing compounds are most appropriate for your project, we've listed them below along with some basic characteristics regarding their performance:

Collections: All Products Buffing Wheels and Metal Polishing Compound Metal Polishing Polishing Compounds Wheel Polishing Machine Supplies

Category: Airstream Polishing Kit Aluminum Mini Kit Buffing Wheels and Metal Polishing Compound Forged Mini Kit Lifted Truck Detailing & Restoration Kit Metal Polishing & Big Rig Restoration Kit Metal Restoration Polishing Compounds Pontoon Boat Polishing Kit Stainless Mini Kit

Renegade Products is the premier manufacturer of polishing compounds that are robust in quality due to our use of premium raw materials. We do not use cheap fillers in our polishing compounds like other manufacturers that prioritize profit over bar quality.

Our cutting compounds are meant to be used with our stiffest buffing wheels to do most of the heavy lifting when it comes to removing the oxidation and surface imperfections on your polished metal projects.

Our metal polishing compounds are used with our Airway Buffing Wheels to increase the effectiveness of the wheel while being used during the cutting, buffing, and polishing process. Some are of a coarser consistency and are usually used to remove scratches while the others are finer, which lends to them being used to shine and finish your work. They should be applied to airway buffing wheels by coating the edges of the airway buffs like below:

Prepping is almost entirely all about sanding. We recommend starting with 180 grit for most wheels and stepping forward to 220 grit, and finishing with 400 grit sanding discs. Most polishing, for aluminum, can be polished well after prepping with 400 grit—finer grits are not usually necessary before polishing with tripoli compound.

Two points to keep in mind that as an alternative to sanding discs one of most popular products is the buff and blend prep discs. Most users will not need green buff and blend discs as those are often used more for concrete wheels. The blue buff and blend disc can help remove dirt, grime, and rust from a wheel to provide a clean surface to begin polishing with compound. We do recommend hitting an aluminum wheel with our maroon satin airway prior to going to polish with tripoli compound as the blue buff and blend disc may leave some hash marks that won't come out without a finer sanding of 400 grit or the maroon airway.

To determine which polishing compounds are most appropriate for your project, we've listed them below along with some basic characteristics regarding their performance: