Renegade's original Red Line

•Soap & Dressing & Savage APC

Kits

$49.00

•2oz Bottles of hand sanitizer and surface disinfectant spray to leave in your vehicle, purse, or other convenient areas

•Full size bottles for work or home

$49.00

$49.00

$49.00

Menu title

This section doesn’t currently include any content. Add content to this section using the sidebar.

Your headline

Image caption appears here

$49.00

Add your deal, information or promotional text

FAW9X3X5/8N2-16PDF-SO

$21.00 USD

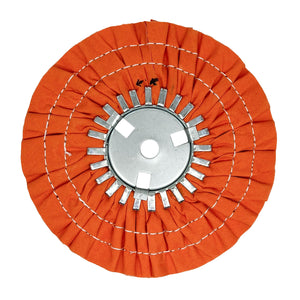

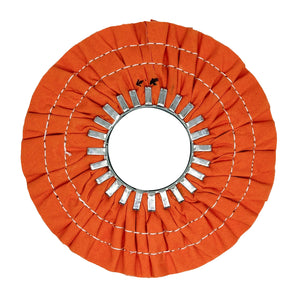

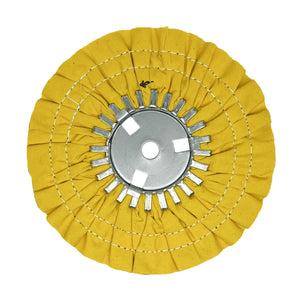

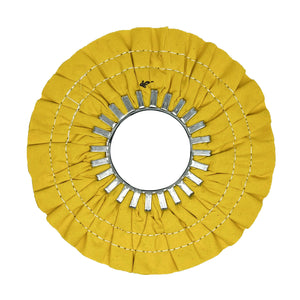

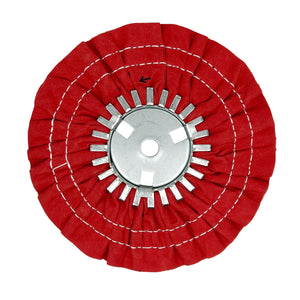

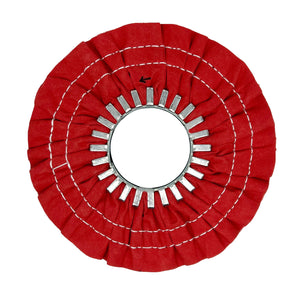

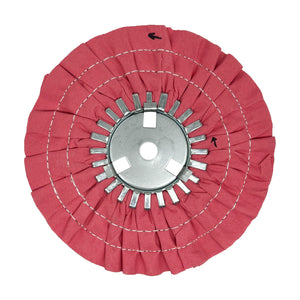

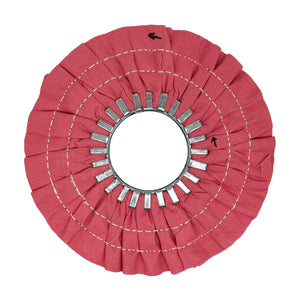

Our Stitched Buffing Wheels are meticulously designed to provide more compact and closely bound buffing fibers, resulting in a tighter construction as compared to the regular Airway Buffs. This unique stitching method ensures extended durability and heightened stiffness for your buffing wheel, allowing for a more intense and precise polishing experience.

Shine metal to perfection using the edge of the buffing wheel. This technique, known as edge buffing, is particularly effective when paired with an angle grinder, the right buffing wheel, and a suitable compound.

For those tough spots on aluminum and stainless steel wheels, use a smaller Spiral-Stitched Buffing Wheel alongside the correct metal polishing compound as detailed above.

Keep your buffing wheels efficient and in top shape by regularly raking them.

While the buffing wheel rotates at its operational speed, secure the rake and either hold it against a stationary bench grinder or lathe. If using a grinder, anchor the rake with your feet and approach with the grinder cautiously. Why Rake? Over time, buffing compound accumulates on the wheel, hardening and occasionally burning. This buildup reduces wheel efficiency and makes for a rougher polish. When you see a drop in metal dust while buffing, it's time to rake and reapply your polishing compound.

MAKITA 9237C- The best 3,500 RPM polishing machine (PROS & BEGINNERS)

First/Cut Stage: 3,000 to 3,500 RPM

Second/Color Stage: 2,200 to 2,800 RPM

Third/Finish Stage: 1,800 to 2,200 RPM.

Our Stitched Buffing Wheels are meticulously designed to provide more compact and closely bound buffing fibers, resulting in a tighter construction as compared to the regular Airway Buffs. This unique stitching method ensures extended durability and heightened stiffness for your buffing wheel, allowing for a more intense and precise polishing experience.

Shine metal to perfection using the edge of the buffing wheel. This technique, known as edge buffing, is particularly effective when paired with an angle grinder, the right buffing wheel, and a suitable compound.

For those tough spots on aluminum and stainless steel wheels, use a smaller Spiral-Stitched Buffing Wheel alongside the correct metal polishing compound as detailed above.

Keep your buffing wheels efficient and in top shape by regularly raking them.

While the buffing wheel rotates at its operational speed, secure the rake and either hold it against a stationary bench grinder or lathe. If using a grinder, anchor the rake with your feet and approach with the grinder cautiously. Why Rake? Over time, buffing compound accumulates on the wheel, hardening and occasionally burning. This buildup reduces wheel efficiency and makes for a rougher polish. When you see a drop in metal dust while buffing, it's time to rake and reapply your polishing compound.

MAKITA 9237C- The best 3,500 RPM polishing machine (PROS & BEGINNERS)

First/Cut Stage: 3,000 to 3,500 RPM

Second/Color Stage: 2,200 to 2,800 RPM

Third/Finish Stage: 1,800 to 2,200 RPM.